Esungulwe ngo-2009, i-alicosolar yenza amaseli elanga, amamojula, kanye nezinhlelo zamandla elanga, ezibandakanyeke kakhulu ocwaningweni nasekuthuthukisweni, ekukhiqizeni nasekuthengisweni kwamamojula we-PV; Iziteshi Zamandla kanye nemikhiqizo yohlelo njll. Ukuhanjiswa kwayo okuhlanganisiwe kwamamojula we-PV kudlule i-80gg.

Kusukela ngo-2018, i-Alicososolar yandisa ibhizinisi le-Solar PV Development, imali, ukwakhiwa, ukwakhiwa, ukusebenza kanye nokuphathwa kwezixazululo zokuhlanganiswa kohlelo lwe-One-Stople yamakhasimende. I-Alicosolar ixhumekile ngaphezulu kwe-2.5gw yezitshalo zamandla elanga kugridi emhlabeni jikelele.

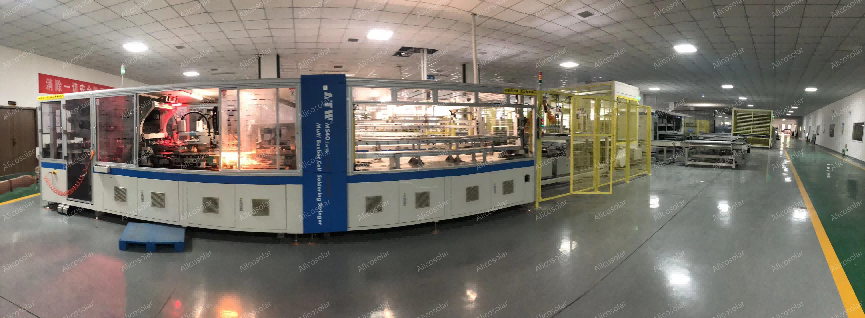

Isitolo Sethu Somsebenzi

Indawo yethu yokugcina izinto

Zonke ibanga iseli yelanga, ukukhululwa ekuhlolweni

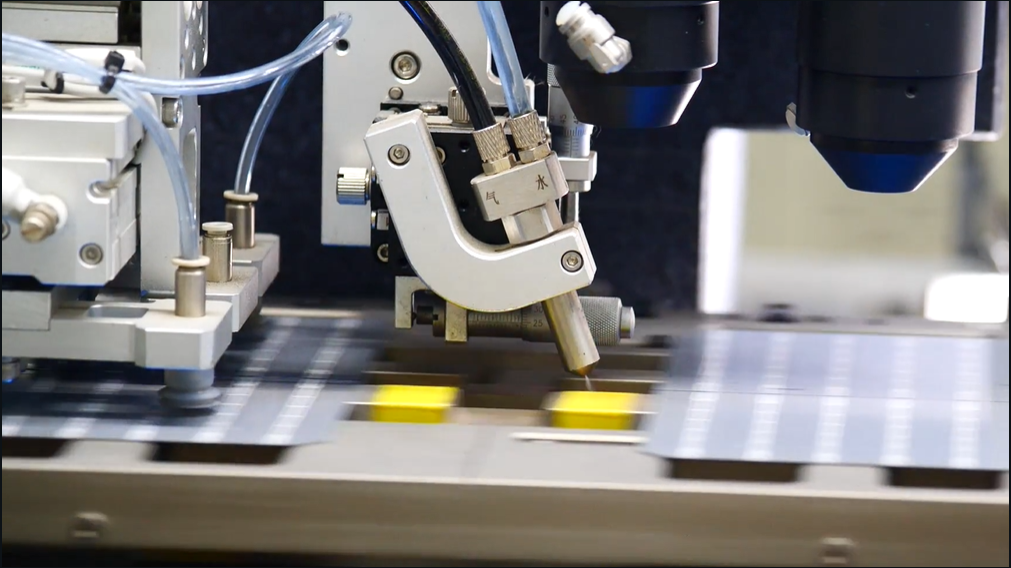

Isinyathelo 1-Laser Sclibleng, Kukhulisa kakhulu ukuphuma kwe-wafer ngeyunithi ngayinye

Isinyathelo 2-String Welding

Ngaleso sikhathi-samiating ar ukunamathela okufuthezele, i-EVA bese ulindile phezulu

Isinyathelo 3 - Umshini wokuthayela okuzenzakalelayo kwingilazi yokulinda ne-EVA

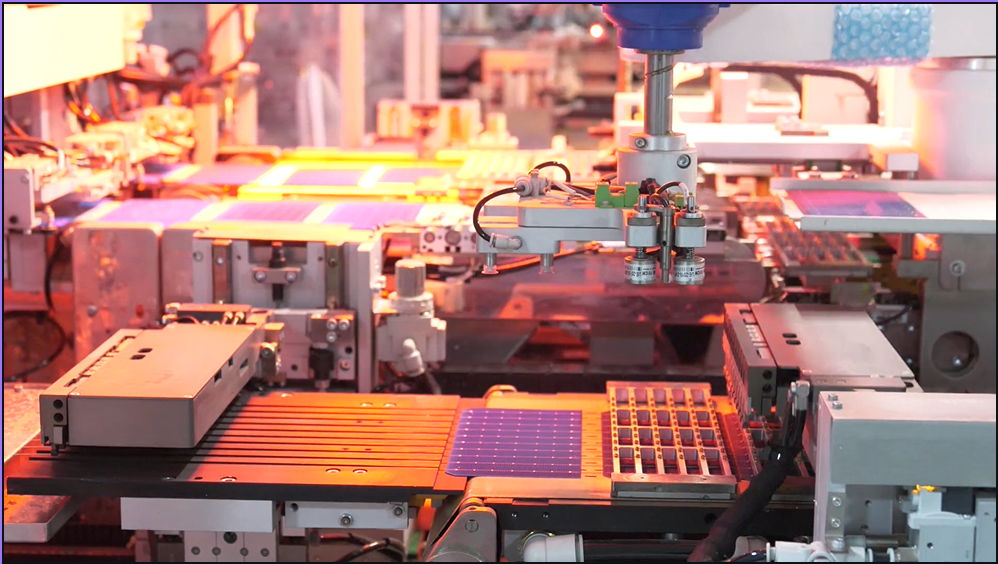

Isinyathelo 4-I-Wamid Welding kanye ne-Lamination.

Sebenzisa umshini wokufaka we-welding we-laming (ama-welding ahlukene amaseli amasayizi ahlukene) ukuwela maphakathi nawokuphela kwentambo yeseli elithayishiwe ngokulandelana, bese wenza indawo yokuhlala ephezulu, bese unamathisela ngokuzenzakalela itheyiphu yokushisa ephezulu.

Isinyathelo 5 - Intambo yebhethri, ingilazi, i-EVA, kanye ne-backplane zibekwe ngokuya ngezinga elithile futhi zilungele ukugcwala.

Isinyathelo 6-Ukubukeka nokuhlolwa kwe-El

Ukuhlola ukuthi ngabe kunezimbungulu ezincane, noma ngabe ibhethri liqhekekile, amakhona alahlekile, njll. Iseli elifakiwe lizobuya.

Isinyathelo 7-Lamised

Ingilazi ebekwe yingilazi / yebhethri / i-EVA / Back Sheet Pre-Press izongena ngokuzenzakalelayo e-laminator, futhi umoya osemotweni uzophonswa ngokuvutha, bese i-EVA izoncibilika ngokushisa ukuze ibhondi lokubopha ibhethri, ingilazi kanye Ishidi elingemuva ndawonye, ekugcineni bathathe umhlangano ngokupholisa. Inqubo yokuqalisa isinyathelo esiyisihluthulelo ekukhiqizweni kwezakhi, kanye nokushisa okunamafutha nesikhathi sokushisa kunqunywa ngokuya ngezakhiwo ze-EVA. Isikhathi sokujikeleza kwesimanga singamaminithi ayi-15 kuye kwayi-20. Izinga lokuphumula le-135 ~ 145 ° C.

Izilawuli Zenqubo Eyisisekelo: Ama-Bubble Air, imihuzuko, imigodi, ama-bulges kanye splinter

Isinyathelo 8-Module Procul Processing

Ngemuva kokukhanya, izingxenye ezihlanjululwe zigelezele kuhlaka, futhi udonga olungaphakathi lodonga lwangaphakathi lushaywa ngokuzenzakalelayo ngemuva kwesikhundla somshini, bese uhlaka oluzenzakalelayo lushaywa futhi lubekwe e-laminator. Amakhona ezinto alungele ukufakwa kobunjiniyela.

Izilawuli Zenqubo Eziyinhloko: Imigodi, imihuzuko, imihuzuko, ukuchitheka kwama-glue phansi, ama-bubble wokufaka kanye nokushoda kwe-glue.

Isinyathelo 9 - Ubuqili

Izingxenye ezinohlaka kanye nebhokisi lokuhlangene elifakiwe esiteshini sangaphambili zifakwa emgqeni welapha ngomshini wokudlulisa. Inhloso enkulu ukwelapha i-sealant ifakwe lapho kufakwa ifreyimu nebhokisi lokuhlanza, ukuze kuthuthukiswe umphumela wokubopha futhi kuvikeleke izingxenye ezivela emvelweni kwangaphandle okunokhahlo. amathonya.

Izilawuli Zenqubo Esemqoka: Isikhathi sokwelapha, izinga lokushisa kanye nomswakama.

Isinyathelo 10 - Ukuhlanza

Uhlaka lwengxenye yengxenye nebhokisi lokuhlanza eliphuma kulayini welapha liboshwe ngokugcwele, futhi i-sealant yelaphekile ngokuphelele. Ngomshini wokujikisa we-360-degree, inhloso yokuhlanza izinhlangothi zangaphambili ze-Acgn on Umumo Umugqa iyatholakala. Kuyinto elula ukupakisha kumafayela ngemuva kokuhlolwa okulandelayo.

Ukulawulwa Kwenqubo Okusemqoka: imihuzuko, imihuzuko, imizimba yakwamanye amazwe.

Isinyathelo 11-Test

Kala amapharamitha kagesi kagesi ukunquma amazinga engxenye. Ukuhlolwa kwe-LV - ukukala amapharamitha kagesi wokusebenza ukuze unqume ibanga lengxenye.

Isikhathi Sokuthumela: Jul-28-2022